Technical

TECH TUESDAY: How late-season upgrades could be pivotal in the Alpine vs McLaren fight for P4

Share

Although Alpine are still engaged in a fight with McLaren for fourth place in the constructors’ championship, it’s quite clear that behind the ‘big three’ teams, the A522 has been the most consistently competitive car on race day in 2022.

In contrast to cars from the Enstone team in recent years – and in contrast to this year’s McLaren – its performance appears equally strong across a wide variety of track types and it has responded well to development.

For Singapore this weekend, Alpine are expected to introduce a further significant aero upgrade, part of a continuous process which has been facilitated by a highly cost-effective concept in this cost-capped age.

READ MORE: Alonso says Alpine are 'overachieving' in fight against McLaren

“We’ll carry on with updates on the car for the rest of the season,” says Technical Director Matt Harman. “We still have the financials to do that and we still have ideas…”

The team numbers around 100 fewer staff than the biggest, giving some budget headroom for car development, but the car itself has been designed with a range of modular bodywork parts so that, for example, the floor or sidepods have been updated with just a patchwork of changes rather than the whole component.

Alpine are continuing to develop the A522, with further updates expected in Singapore

Alpine are not unique in this modular approach this year, but have probably taken the concept further than anyone else.

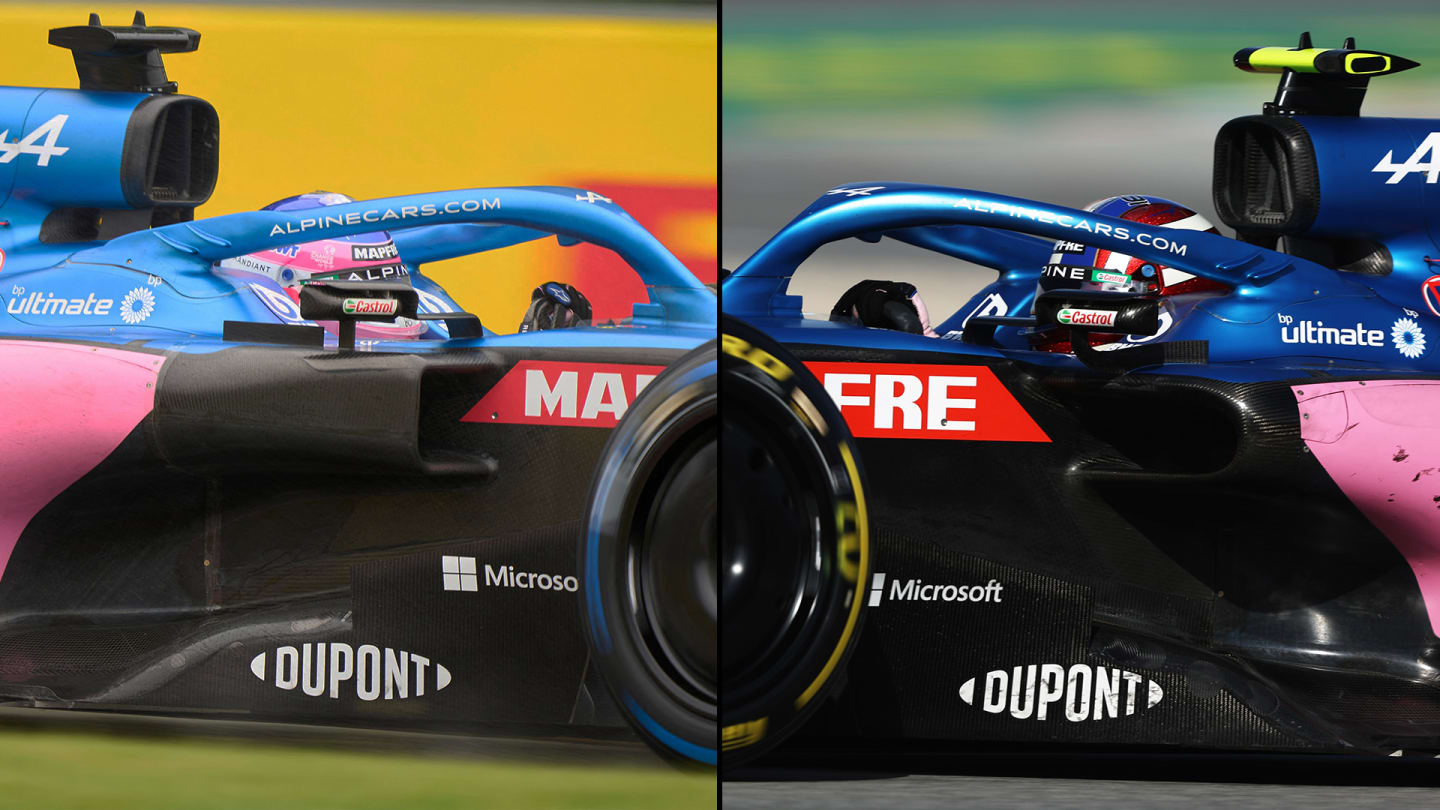

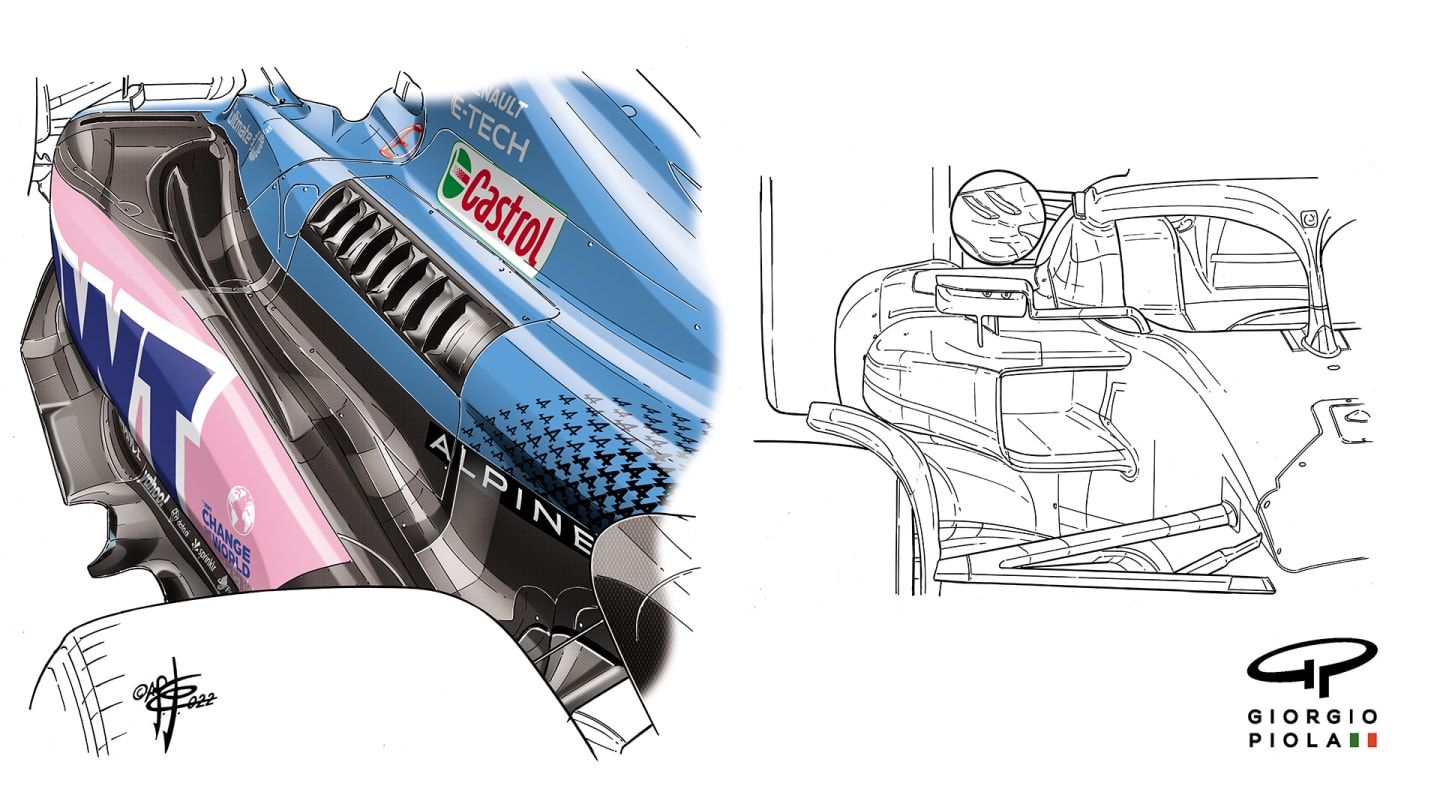

As a case in point, at Baku a new radiator inlet arrangement at the front of the sidepod was introduced.

With a narrower, but deeper and more forwards-placed, inlet for the radiator air, it allowed the front of the sidepod to be angled inwards, which the team claimed reduced drag without any reduction in downforce, and which gave it a better control of the airflow wake coming off the front tyres.

It can be seen that although the front of the sidepod shape is totally different, it is simply a new add-on section to the existing pod.

Similar changes were made to the exposed front section of the floor over the course of the season, and it was common to see different shades of carbon there where the new sections had been blended into the existing floor.

New, narrow and deeper radiator inlet (left), and old, wide and shallow inlet (right)

The skeleton of the car, with all bodywork pieces removed, is exceptionally compact, facilitated by the latest technologies in radiator cores and associated plumbing and by how strong the carbon structure is in the right places, whilst still being weight-efficient.

This is at the heart of how the cost-effective modular approach has been facilitated.

“We worked incredibly hard for a number of years before these regulations started to put new technology on our race car,” explains Harman. “What that’s done is given us a really strong backbone. We’ve got very efficient technologies in there and that allows us to focus on our aerodynamics department and our mechanical performance items.

READ MORE: Alfa Romeo confirm Zhou Guanyu to stay on for 2023

“It’s all about aero-enablement. We wanted to make sure that every single aspect of the car is supporting or promoting aero volume. We want to give our aerodynamicists the maximum amount of real estate to express themselves.

“There’s nothing in the way. It’s only our own ideas that are limiting us. That’s important and a big part of what has allowed us to move forward.”

Alpine introduced a Ferrari-like trench between the upper sidepod and engine cover at Silverstone (left), and a new radiator inlet arrangement at Baku (right), which gave lower drag for no penalty in downforce

The radiator inlet change was relatively easily accomplished as it didn’t require any re-arrangement of componentry beneath the bodywork.

Similarly, the Silverstone upgrade saw a further change to the profiling of the front of the sidepod, which created a lot more exposed floor ahead of the radiator inlet and a more pared-away bodywork around the rear and a Ferrari-like valley between the sidepod edge and engine cover.

Again, this was relatively easily achieved because of the space the aerodynamicists had to work with – as was the re-siting of the radiator exit at the rear from below the exhaust to above.

A very strict cost-benefit analysis is made by all teams when introducing new development parts.

Earlier in the season, the team’s Chief Technical Officer, Pat Fry, explained how targeted that approach has been at Alpine: “A front wing is the most expensive aero development part. If you replace the whole wing, you're up to 100,000 Euros.

“So you think twice about whether a modification is worthwhile. If a new profile in one part of the floor brings you more benefit, you’d go for the floor.

Alpine lead McLaren by 18 points in the battle for P4 with six races remaining in 2022

"The predicted improvement in the lap time is calculated against the costs. We get back a factor of 10 more on the floor than on the wings and, if I have to choose between 2kg of weight reduction or four points of downforce, I take the weight reduction. That's what guarantees you lap time.”

Good simulation is at the heart of the approach to development.

“We can’t be complacent on that,” says Harman, “because correlation can change in the blink of an eye. But at the moment we are very confident of our correlation and that allows us to keep developing the car through to the end of the season, without necessarily the need for the wind tunnel, which is now needed more for the 2023 car.”

READ MORE: McLaren reveal special livery for Singapore and Japan as F1 returns to Asia

The Enstone technical team will be hoping their targeted efficiencies will make the crucial difference in that fight for fourth in the constructors’ table.

With McLaren also expected to bring upgrades to Singapore, an intriguing sub-plot to the championship story is playing out.

YOU MIGHT ALSO LIKE

Feature NEED TO KNOW: The most important facts, stats and trivia ahead of the 2025 Emilia-Romagna Grand Prix

News How to stream the Formula 1 2025 Emilia-Romagna Grand Prix on F1 TV Premium

News Hamilton gets set for ‘very special’ first Ferrari home race as he shares ‘dream I’m working towards’

News Verstappen reveals details of Nurburgring Nordschleife test after lap record speculation