Technical

How Niki Lauda's final title-winning car, the 1984 McLaren MP4/2, changed F1

Share

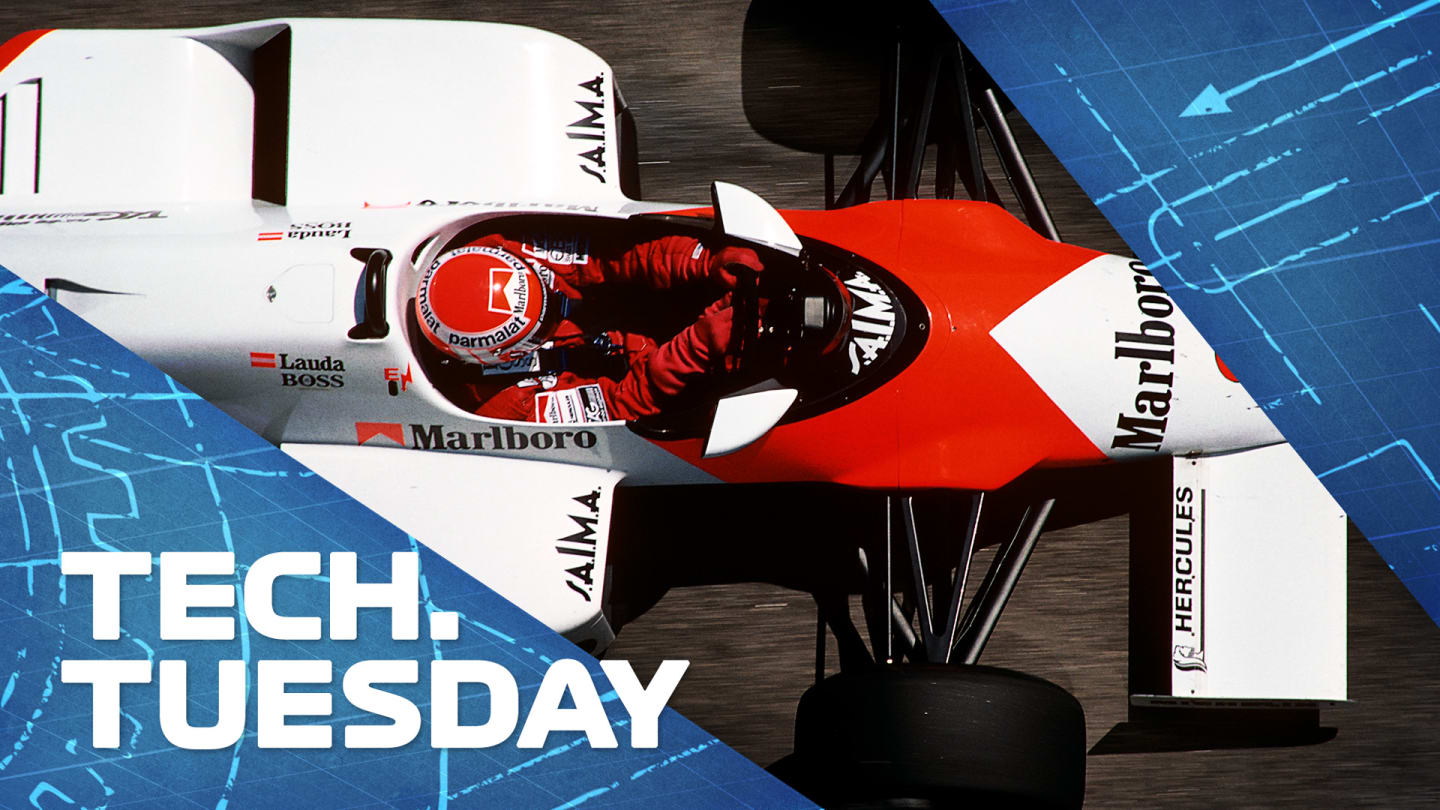

This week marks a year since Niki Lauda passed away and, in technical tribute, Mark Hughes takes a look at the car in which he won his third and final world championship: the 1984 McLaren MP4/2-TAG Porsche. Part evolution, part revolution, this car held off the likes of Ferrari, Lotus and Brabham to dominate the championship with Lauda and team mate Alain Prost winning 12 of the 16 races between them.

It was McLaren’s first pukka turbocharged F1 car after holding out against the turbos with the normally-aspirated Cosworth DFV for several years.

Designed by John Barnard, its superiority over the competition was borne of the exceptional efficiency of its Porsche-designed engine and equally effective aerodynamics which in turn derived, in part, from the architecture of that engine, which Barnard had specified himself.

Using Porsche as a consultant engineering company to design and build an engine to his own requirements, Barnard was able to integrate car and engine in a way far in advance of the competition.

The McLaren-TAG MP4/2, with which Lauda took five wins to lift the world championship in 1984

The core of the car was based very much on Barnard’s original ‘wondercar’, the 1981 MP4/1, which introduced carbon-fibre chassis to F1, giving a vastly superior stiffness to weight compromise to the previous generation honeycomb aluminium tubs – which Williams were still using in 1984.

But the running gear around the tub was extensively modified to cope with the much bigger stresses of the more powerful – and heat-generating – turbocharged engine.

READ MORE: Under the bodywork of the Ferrari 312B3 on the anniversary of Niki Lauda's first F1 win

Radiator surface area needed to be significantly increased compared to the naturally-aspirated car, but so too did brake cooling because of the much greater speeds being attained. This challenge was intensified through Barnard’s switch to carbon brakes, a technology still very much in its infancy.

Carbon discs were experimented with as long ago as 1976, but by ’84 only McLaren had made them sufficiently reliable to use all the time. Barnard worked with the French SEP carbon composites company to come up with a carbon disc featuring radial cooling holes drilled into it – now a standard, and much more intricate, practice – that allowed the heat within the disc’s core somewhere to escape.

The MP4/2 was built with a carbon-fibre chassis, first introduced to F1 in 1981 by John Barnard

Carbon discs will oxidise into nothing if they run too hot for too long. But they will not work properly unless they are at very high temperatures. The ideal temperature range is a very narrow one, at between 600-800-degrees C.

The breakthrough on the McLaren was in designing the disc, the wheel upright and the caliper in a way that allowed it to be in this narrow temperature window. Barnard devised what became the standard fixing system to allow for the differing expansion rates of carbon fibre and the aluminium components needed to secure it to the wheel hub.

WATCH: A history of technical innovation in F1

The brake calipers needed to be made of higher quality alloys than before, with better heat dissipation qualities and lots of fins to increase surface area. The wheel uprights too carried very intricate design for cooling channels.

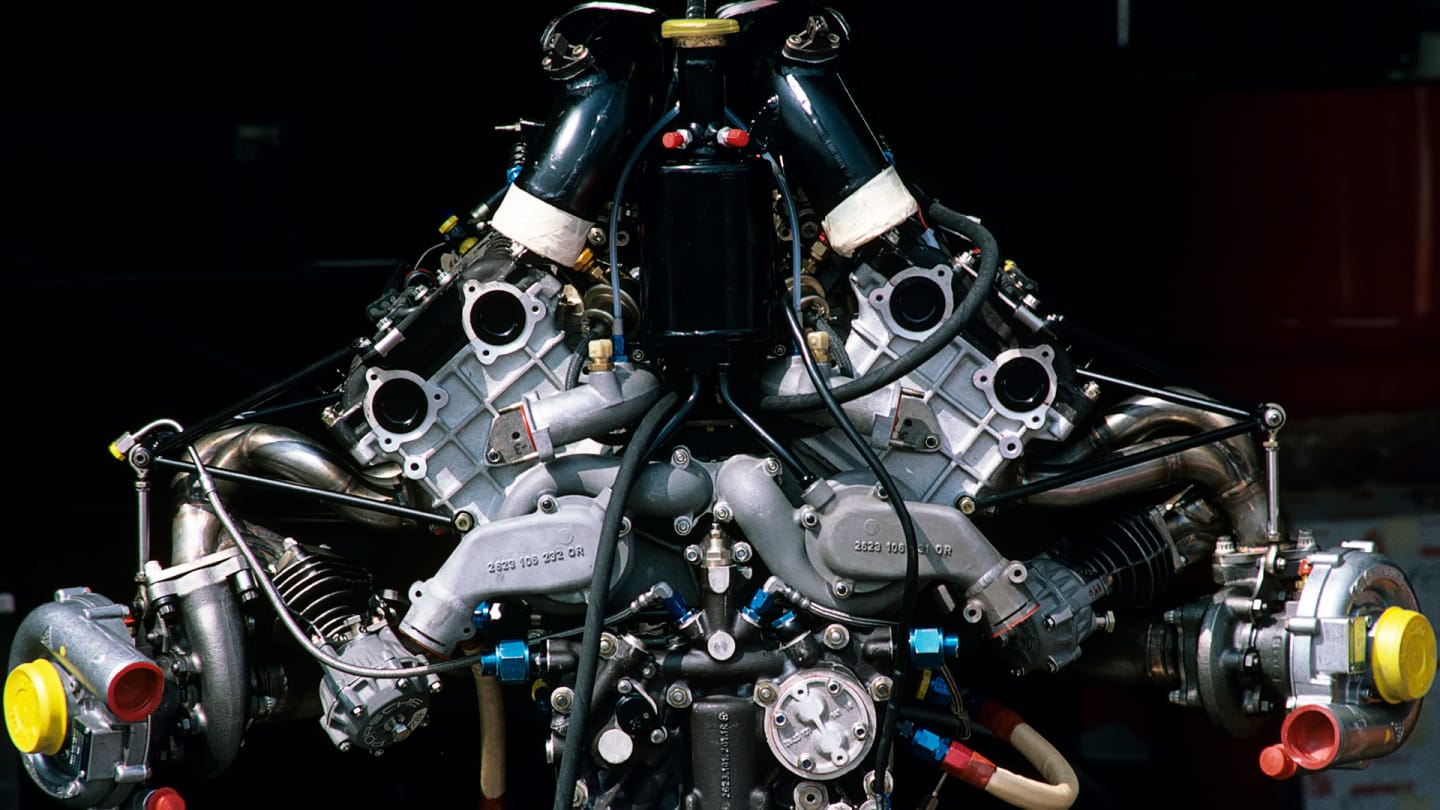

For the engine itself Barnard was dissatisfied with the layout and dimensions of all the existing turbo F1 engines available to purchase, including the Renault V6 and BMW straight-four.

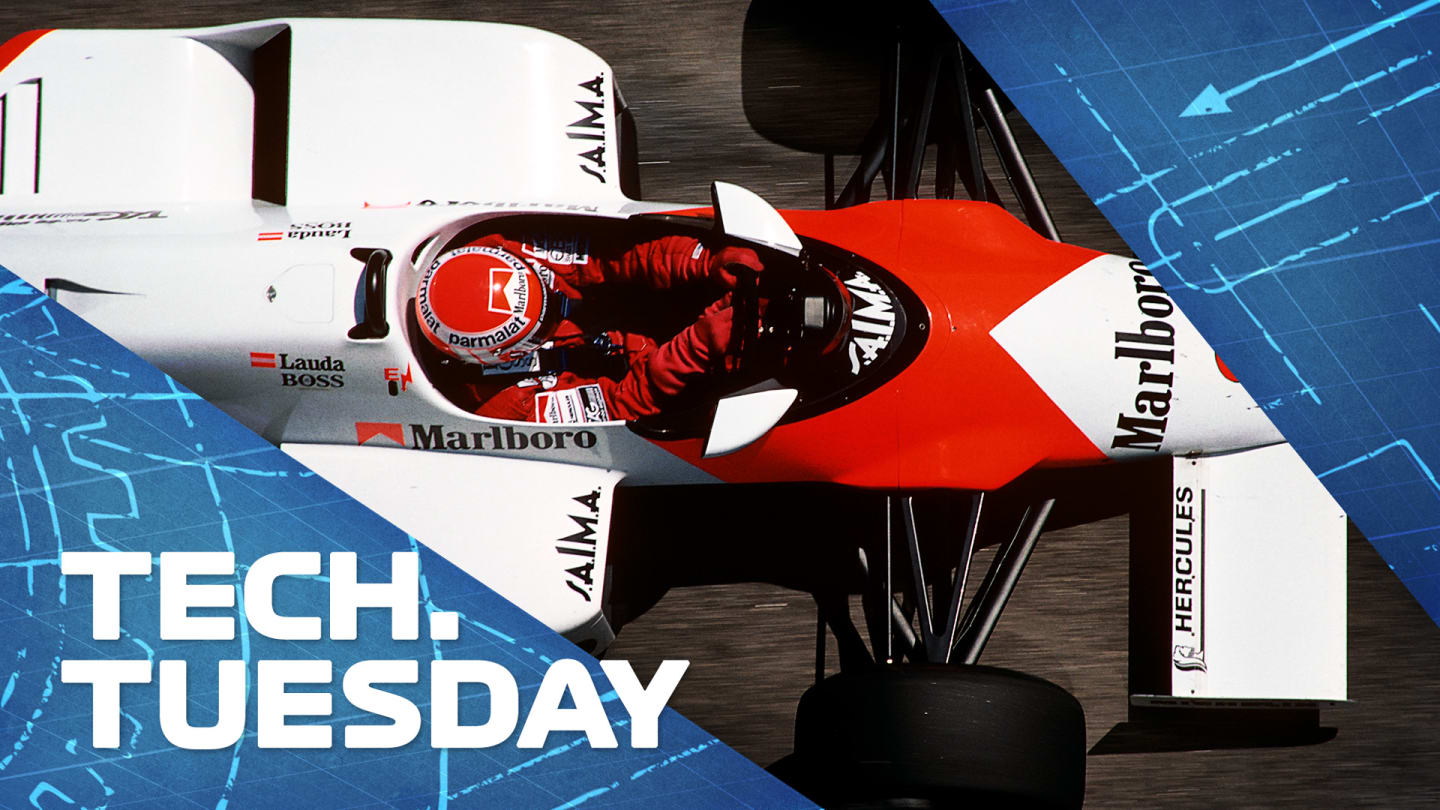

The TAG/Porsche TTE PO1 1.5 V6 Turbo engine - made narrow to match the chassis

Because the concept of the car was being laid down before the FIA had banned ground effect floors (a ban which came into effect from 1983), Barnard had made the central tub as narrow as possible so as to maximise the area of the ground effect-inducing venturis in the sidepods.

Hence, he wanted a narrow engine to match the narrow chassis.

READ MORE: 9 reasons Dallas ‘84 will never be forgotten

The Renault was too wide and had too much clutter for Barnard’s taste. The BMW, whilst narrow, could not be used as a structural part of the car and had to be mounted on a framework.

Barnard insisted to team boss Ron Dennis that they needed to commission their own engine, to dimensions and external proportions laid down by Barnard. Dennis gave his designer his support and set about finding the money to have such an engine designed and built by Porsche.

The Lotus-Renault 95T was powered by a Renault engine with a bigger bore, and larger size, than the TAG engine

Porsche’s Hans Mezger worked hand-in-hand with Barnard in defining the hard points of the engine’s design. It would have a narrow 80-degree vee to maximise the ground effect-generating area around its lower regions.

Its various pumps, drives and necessary ancillaries would all be mounted on the front of the engine, rather than the side, again cleaning up the aerodynamic flow around it.

READ MORE: Why McLaren and Mercedes have joined forces again for 2021

The engine had a less aggressive bore size than the Renault at 82mm (versus 86mm). Although the concomitant longer stroke made the engine taller, a smaller bore allowed better heat control of the piston crown and therefore reliability, a very important consideration with the super-high temperatures generated by a turbocharged engine.

Dennis agreed to fund the initial design stage of the engine – meaning the design rights would therefore be owned by McLaren, not Porsche.

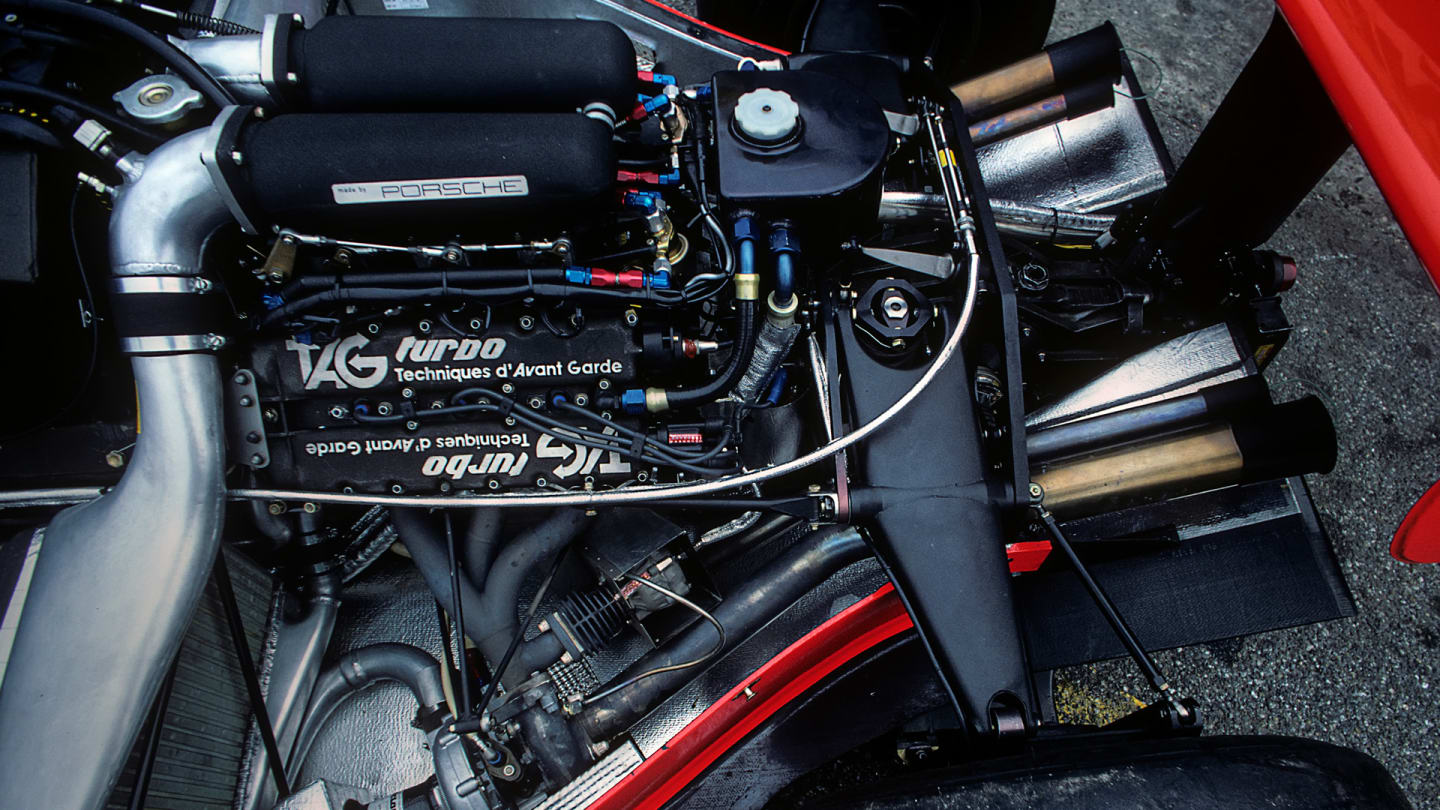

Bosch supplied a state-of-the-art ignition and injection system that helped massively with reliability and fuel-efficiency

This empowered Barnard to dictate to Porsche what he needed. To pay for this custom-made engine by Porsche, Dennis eventually brought in Mansour Ojjeh of Techniques Avant Garde as a partner – hence the TAG badging of the engine – and Ojjeh has been a shareholder in the team ever since.

Key to the engine’s effectiveness was a highly sophisticated (for the time) electronic ignition/injection control by Bosch. This system was developed specifically for the engine by the company’s Udo Zucker. It allowed for humidity, altitude, and the load the engine would be under.

READ MORE: Under the skin of Schumacher's first Ferrari winner

A great deal of development time would be spent isolating the electronics from sudden electro-magnetic spikes, which were potentially disastrous for the engine.

Another novel feature for the time was the engine’s sequential fuel injection, which supplied the fuel to each cylinder just before the firing stroke, each injector working individually. Existing engines had non-sequential injection. Sequential was much more fuel-efficient, a vital advantage in regulations that stipulated a maximum-permitted fuel usage of 220 litres.

Twin KKK (Kühnle, Kopp & Kausch) turbochargers (above, with yellow caps) bookended the engine, compressing at 3.2 bar for racing

With non-sequential injection systems, the whole engine needs to complete a revolution before the air:fuel ratio can be changed. With a sequential system that’s no longer necessary and the changes can be made much more rapidly, maximising fuel efficiency, power – and throttle response.

Twin KKK turbochargers were used. The ideal trade-off between ultimate power and throttle lag reduction varies between circuit layouts and this was resolved by using different size turbos for different tracks.

Uniquely, the turbos were ‘mirror images’ of each other in the way they turned. This neutralised the torque reversal from side-to-side when on-throttle or off, improving stability. It was another Barnard stipulation and cost a lot of development money.

With the turbos and all ancillaries fitted, the engine weighed 149kg, which was around 12kg lighter than the Renault V6, and 2kg lighter than the Ferrari.

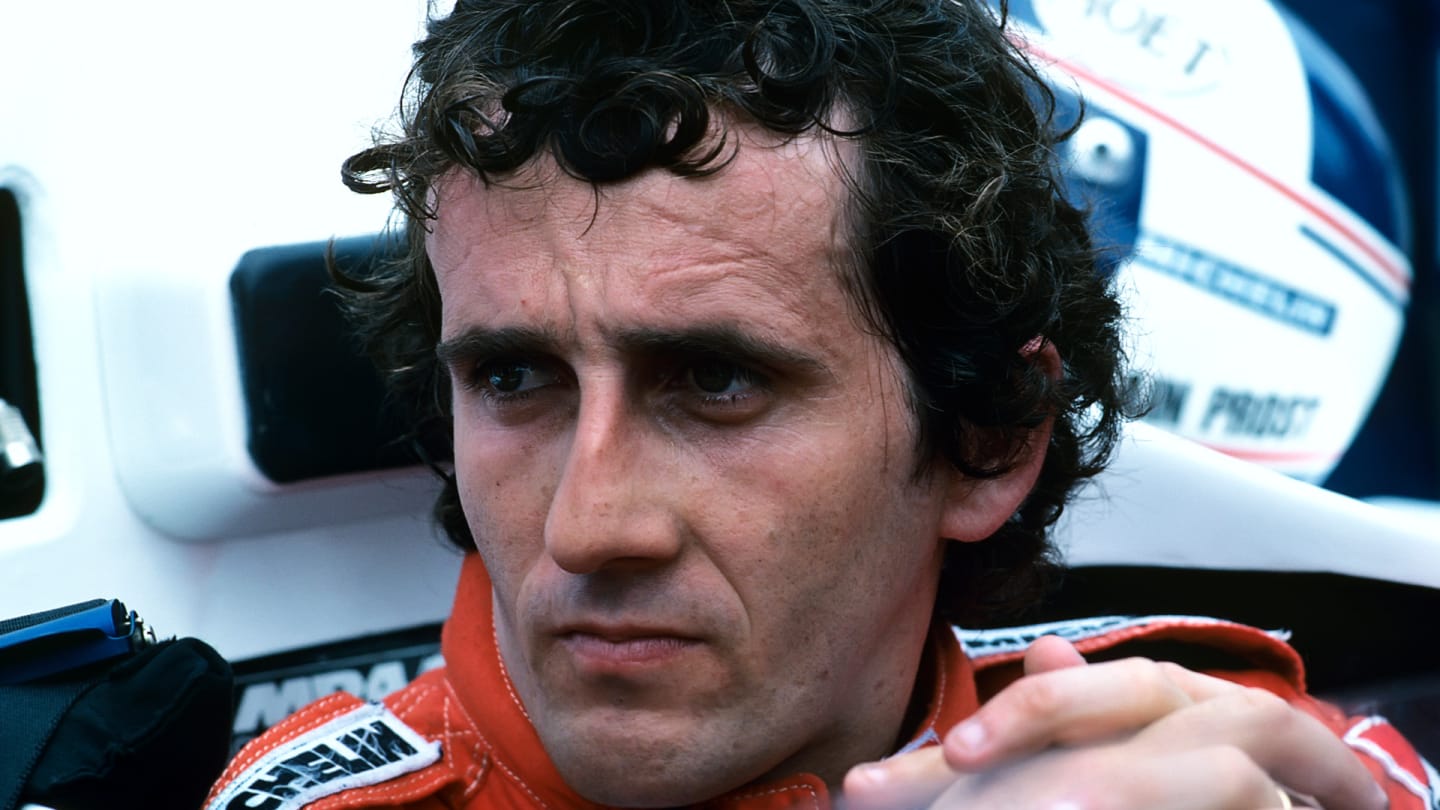

Prost took all three of McLaren's pole positions in 1984, but lost out on the title by the smallest margin in F1 history

The turbos compressed the inlet mixture at 3.2 bar for racing, quite a tame figure compared to the 4-bar plus being achieved elsewhere. A decision was made not to incur the expense of a qualifying level of boost and consequently in 1984 it gave only around 890bhp (still well up on the old DFV’s 520) compared to well over 1,000bhp for the BMW and Renault.

But its vastly greater fuel efficiency allowed it to race with over 800bhp for the full race distance, significantly more than any rival at the time. Hence although the car won 75% of all the races in ’84, it set pole only three times (18.75%).

PODCAST: Prost on his amazing career, his unique relationship with Senna and his 80s rivals

All of those poles were set by Prost, as Lauda – who disliked the improvisation needed to maximise the car around a different boost pressure in qualifying to what he’d be using otherwise – despaired of being able to match Prost’s single lap pace and instead devoted his practices to perfecting the race set-up of his car.

Prost won seven races to Lauda’s five, but the latter clinched the championship at the final round by half a point (half points having been awarded for the rain-shortened Monaco race).

Lauda won the championship by just half a point over Prost, whose rain-shortened Monaco Grand Prix win yielded just 4.5 points

When the FIA announced, at short notice, that the 1983 regulations would be for flat-bottomed cars and that the venturi floors were banned, it came as a great blow to Barnard who’d based the whole configuration of chassis shape and engine around maximising the venturi area.

But McLaren’s response to that rule change – introduced in the 1983 DFV-engined car but still an intrinsic part of the MP4/2 in ’84 – created a different advantage over the opposition. The ‘coke bottle’ profile of the sidepods at the rear – where they sweep in towards the centre of the car in plan view – directed the airflow at high speed between the rear wheels.

READ MORE: Under the bodywork of 1986’s best F1 car, the Williams FW11

This not only reduced the drag of the rear tyres but the accelerated airflow created a low pressure area behind the floor which effectively sucked the underbody airflow through faster. The faster that flows, the more downforce is induced.

A diffuser at the rear of the flow was shaped to enhance this effect and then fed that flow to the underside of the rear wing – increasing the downforce generated from that too. The greater the pressure difference between the upper surface and underside of the wing, the faster the air is induced to flow over it, and that pressure difference resulting from having a faster flow on the underside than the upper surface is what creates the wing’s downforce.

The diffuser sped up flow under the rear wing, further enhancing downforce

The coke bottle idea is widely credited to Barnard’s design assistant Alan Jenkins and is still a standard part of F1 design to this day.

Although Barnard had feared that the flat-bottom regulations would take away his planned advantage, the creation of space for the airflow made possible by his narrow chassis/narrow engine stipulation just allowed that advantage to be deployed in a different way.

READ MORE: How Mercedes' 2020 car tackles the W10's biggest weakness

The coke bottle could not been as enhanced without all the space his concept had created. That was at the root of the MP4/2’s aero advantage.

The rear suspension design – introduced on the ’83 car – was also intrinsic to maximising that space around the car’s lower regions. Barnard opted for pushrod activation rather than the more commonplace pullrod.

The coke bottle figure of the MP4/1E was revolutionary in 1983

In this way he was able to get the suspension rockers out of aerodynamic way, even though this increased the centre of gravity height. It also allowed a stiffer installation between wheel and suspension, giving better ride and handling.

Ride, keeping the car’s ride height as stable as possible, is a very important for consistent aerodynamic performance.

READ MORE: 10 of the best injury comebacks in F1 history

It can be appreciated then just what a beautifully integrated project the MP4/2 was. Its design and concept was of a higher order than any of the competition, setting the tone for McLaren in the further blockbusting years that were coming.

It’s fitting that the end of Lauda’s glorious career should have been part of instigating that new era.

Lauda's last world championship win was in 1984. He retired at the end of the 1985 season

More TECH TUESDAYS

- What does the 2021 aero rules change mean for the cars – and which teams will it hurt most?

- The hidden upside of Mercedes and Alfa's DRS-boosting rear wing

- Under the bodywork of the Ferrari 312B3 on the anniversary of Niki Lauda's first F1 win

- Under the bodywork of the Alfa Romeo ‘Alfetta’ – 70 years after it won the first ever F1 race

- Under the skin of Schumacher's first Ferrari winner

YOU MIGHT ALSO LIKE

News Verstappen admits Russell contact ‘shouldn’t have happened’ in Spanish GP as Dutch driver nears race ban threshold

Podcast F1 NATION: Piastri wins in dominant style as Verstappen gets everyone talking – it’s our Spain GP review

News Hadjar declares points run in Spain ‘a lot of fun’ as Racing Bulls team mate Lawson reflects on factor that ‘screwed’ him

News ‘I prefer to be second than fourth’ – Vasseur bullish as Ferrari jump Mercedes and Red Bull in the standings