1 / 4

Feature

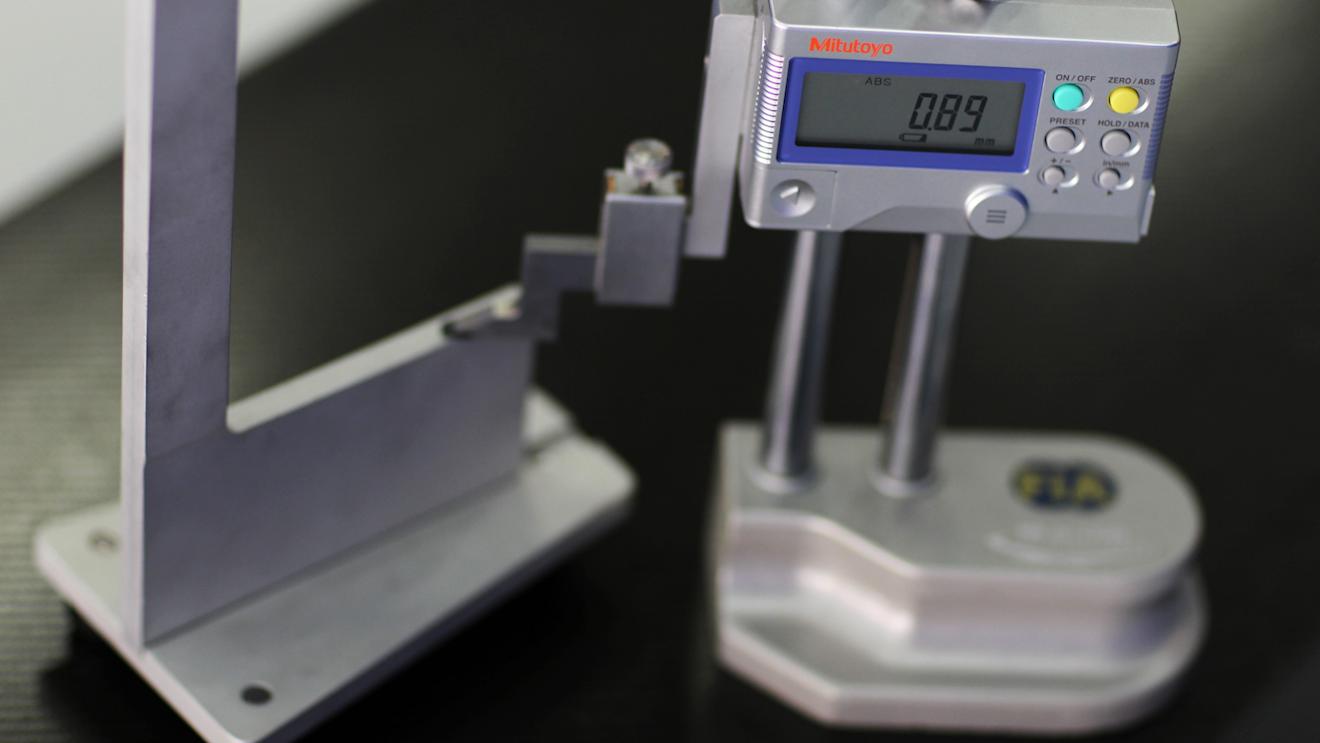

The Watchmen - the role of the FIA's technical team

With Formula One racing going through its biggest set of regulation changes in history in 2014, ensuring a level playing field became a lot harder for governing body, the FIA. But just how do they make sure that every car that hits the track complies with the rules? Read on to find out…

The final moments of Formula One Grands Prix are, on the surface, fairly chaotic. As the chequered flag falls, team members flood the pit wall to wave home winners. The victorious swoop towards them in acknowledgement of a job well done, podium finishers pump the air in celebration, and the rest of the field sweeps by to complete slow-down laps on their way back to the pitlane.

There, the frenzy goes into overdrive. A flood of cars pours towards parc ferme the area where drivers must halt once the race has ended. On the other side of hastily-erected barriers, a swarm of team members and TV crews jostle for position as the top three drivers clamber out of their cars to soak up the admiration before making their way to the podium.

However, look past the champagne spray and adrenaline-fuelled chest bumping and in the midst of the chaos, organisation is once again taking hold. Up and down parc fermé, a small crew of officials checks each car, making sure they’re safe. Car data is then downloaded for analysis, all of which must be done before the final result is published.

It’s not just in the heated moments after the flag falls that these careful checks take place, either. From the moment the cars arrive at each grand prix circuit, the FIA’s 10-man technical crew is on alert, steadily working through a series of tests to ensure that each car conforms to F1’s regulations - making sure the playing field is level. Ten men, up against the ingenuity and brain power of thousands of the brightest minds in motor sport, all of whom are seeking to push the rules as far as possible in pursuit of the infinitesimal time advantages which define victory in Formula One. It’s a hugely demanding task, but one that in 2014 has become even more complex.

This season sees the sport undergoing the biggest regulation change in its history. The arrival of a new V6, 1.6-litre turbocharged hybrid power unit featuring extensive energy recovery systems means the FIA technical team is dealing with a radically different F1 landscape.

“It’s a different world, it has nothing to do with the old cars,” says technical delegate Jo Bauer, who heads up the 10-man team that reports to race director Charlie Whiting.

“The whole area we are involved in is completely different. We learned a lot through [pre-season] testing, and we need to be organised just to get through it. It’s going to be difficult and time-consuming this year, but we are prepared.”

The shape of Grand Prix weekends has largely been fixed in recent years, with the main body of the technical crew setting up at a circuit on the Wednesday before the race (Tuesday in the case of long-haul events and Monaco) and the software analysis team setting up a day later. The FIA technical area is established in the pitlane garages, with a measuring platform installed, the trucks that are home to the technical crew for the weekend are readied and the fuel testing laboratory is set up.

“On Wednesday, everything has to be operational by lunchtime,” explains Bauer. “The teams then have the choice to come to us and do private deflection tests [in which car elements are tested to check they meet tolerances] or any measurement checks they would like to do, but they have to book this in advance.

“Then, on Thursday at 8.30am, we are at the track for initial scrutineering. We brief the scrutineers and the platform crew, and then start at 10am. This is largely to check that all the cars meet our safety requirements.

“Every country provides 30 scrutineers and we split those into a platform crew, tyre checkers and garage scrutineers. Each car is scrutinised and this has to be done before 4pm when we submit a report to the stewards who then publish the entry list.”

A weekend of old would then involve the technical team working steadily through a regime of checks. These would include testing fuel samples from the teams before and after each track session, logging engine use, inspecting seals on components the teams were not permitted to interfere with - such as gearboxes and engine control units - checking tyres and doing software checks on car systems. The work would go on throughout the weekend.

But while the methodology remains the same for 2014 - “we carry out regular checks on all aspects of the cars during the weekend,” says Bauer - the shape of the technical team’s workload has changed dramatically.

Chief among the team’s challenges is F1’s new power unit. From 2006 until this year, F1 raced with a normally-aspirated 2.4-litre V8 engine, the specification of which was frozen for ’07. A known quantity, the V8 provided teams with little room for manoeuvre, as FIA software analyst Olivier Hulot admits:

“It was settled. It had been around for years, so the software inside the standard ECU (engine control unit) was the same for everyone. You could play with a few parameters for control of the V8, but that was it.”

Fast-forward to 2014 and the game has changed - even the word engine has been ousted in favour of the new term ‘power unit’. It’s an apt description for an engineering marvel the like of which has never before been seen in F1.

Aside from the 1.6-litre internal combustion engine, the power unit is made up of two energy recovery systems - one harvesting energy from the car’s braking phase (as with the old KERS) and the other recovering energy from exhaust gases and attached to a new turbo. These systems have required a rethink of the standard ECU brought to the sport by the FIA in 2008.

“Prior to this year all the control software, everything that was managing the engine - the gearbox, differential, clutch and so on - was standard code. The teams had no ability to change that code,” says Alan Prudom, who heads up the FIA software analysis team at the races. “This year the teams have been given more freedom, in that they are able to write some of their own code. It is still within the same standard ECU as last year, but there are some areas we’ve set aside for which the teams can write code. That’s primarily for things like the management of energy recovery systems, the way the energy is balanced around the unit. They can have an influence on choosing strategies for the way in which engine power is delivered, what proportion is from the internal combustion engine and what comes from the battery and the associated motors.

“There’s also a fair amount of freedom on some of the newer technologies such as the turbo management. However, most of the chassis side of things like the gearbox control and clutch differential is still standard software that the teams can only configure, they can’t actually change it.”

These advances mean that whereas before analysis of a team’s use of the ECU was relatively straightforward, this year the FIA technical team must sift through a vast amount of code to ensure teams are conforming to the rules.

“A lot of the work we do for a grand prix is preparation, it’s before the race weekend,” explains Hulot, who is responsible for ECU checks. “Pre-season we visit all the teams, all the engine suppliers and check how they’re connecting the standard ECU to their car systems.

“Then before each race we look at how they configure the standard parameters, making sure this is in compliance with the regulations. Before each session we verify again the configuration of the standard issue.”

And the analysis doesn’t stop there. During each session the FIA’s software analysts have access to live data from the cars, which they look at throughout the weekend, searching for signs of untoward performance.

“We have dashboard-type displays that give us warnings when somebody is running close to the limit in terms of a specific regulation,” explains Hulot. “Largely it’s an exercise in trying to minimise post-event analysis, because after the event it’s too late.”

Allied to analysis of the ECU is an examination of the control units of the new energy recovery systems themselves, a task managed by Andy Leitch.

“The kinetic energy recovery is basically the same as the old KERS - you have the same control electronics going between the battery and the motor. But then it’s doubled up. You’ve got a second motor generator unit on the turbo and also the size of the motors has increased. So instead of 60kW it’s now 120kW,” he says.

“In terms of what we’ll be looking for, there are limits on how much power the kinetic recovery motor generator (MGU-K), can provide. There are also limits on how much energy can be taken in and out of the battery. From a safety point of view we’ve put a maximum voltage of a thousand volts to be used, so we’re making sure the teams don’t exceed that, which they shouldn’t do by design. There’s also a maximum speed permitted for the turbo motor.”

Again the analysis is a mix of pre-race checks and data examination performed in real time.

“The weight of the battery is defined so a team can’t have a really light battery that’s got high capacity. There’s no point in them spending a lot of money trying to get a special battery made that’s going to be a bit lighter because it won’t help - you’ll end up having to put ballast on [the car] to compensate,” he adds. “Those design elements are checked before the start of the season.

“On the car itself we have two sensors: one for the MGU-K and one in the battery to measure how much energy goes in. During running we’re looking at those to see how much energy, how much power, how much voltage is present. And if our sensor fails the teams have to provide a model of the power they’re using, which I can then verify.”

All these systems are also locked, either by physical or software seals, so that the teams are prevented from making adjustments.

Prudom admits that the complexity of the new units has increased the responsibilities of the FIA’s software team, with an extra software analyst taken on to help shoulder the burden.

“I’ve been working in this area of Formula One for 20 years and these are by far the most complicated engines I’ve dealt with - by a factor of two or three,” he says. “They are a far more extreme design than, say, the previous V8s were. So it is extra work for sure and I think everyone, the teams and ourselves, is on a learning curve with them.”

And the learning curve has been steep. Pre-season testing saw every powerplant manufacturer suffer reliability issues, with Renault the worst affected. Despite the difficulties, however, each manufacturer was bound by the new rules to homologate its power unit on February 28th.

“This work was undertaken by our engine expert John Marson,” says Bauer. “Each team must submit a reference power unit that we can check against whatever they’re doing during the year. Basically, it’s the closing of the boxes, so to speak. After that point the only option for the manufacturers to alter the power units is on the grounds of reliability, safety or cost, and that request must then be submitted to the FIA for approval.

“John also looks after power unit checks at the races, making sure that the right components are being used, as the teams are restricted on the number of certain elements they can use,” he adds.

Continued in Part Two

This article, written by Justin Hynes, is reproduced with kind permission from the current edition of AUTO, International Journal of the FIA.

YOU MIGHT ALSO LIKE

Feature Christmas gifts from Schumacher, Google Translate struggles and Raikkonen’s influence – Getting to know the real Jack Doohan

Feature POWER RANKINGS: Where do the drivers rank in the final leaderboard after a rollercoaster 2024 season?

News Kick Sauber recruit rookie Emma Felbermayr for 2025 F1 ACADEMY season

Feature END OF YEAR REPORT: Williams - A mid-season driver swap, countless crash dramas and a true test of determination