Of all the circuits on the calendar, none tests an F1 car’s stopping power quite like Canada. On the eve of this year’s race in Montreal we explain why…

The statistics will tell you that the drivers spend around 72 percent of the lap in Montreal on full throttle, but don’t be fooled: the driver’s left foot - the one used for braking - is given a much greater workout than his right during a tour of the semi-permanent circuit.

Believe it or not the driver has to apply over 930kg of pedal load per lap in Canada - an incredible 65,590kg over the course of the 70-lap race - and it’s all down to the Circuit Gilles Villeneuve’s unique blend of high-speed straights and tight bends.

The proliferation of long straights encourage the teams to run low-drag set-ups in order to maximise top speed, meaning not only do cars reach corners at a higher than average velocity, they also have less aerodynamic resistance than usual to slow them down when the driver eventually hits the brakes.

Then there’s the braking zones themselves. In total there are seven in Montreal, four of which are approached at 300 km/h (186 mph) or above, and five of which see the drivers pulling more than 4.3G under deceleration. That’s some extremely heavy braking.

According to Brembo, who supply brake discs, pads and callipers to much of the field, the heaviest stop of all comes at the Turn 13/14 chicane at the end of the lap when drivers slow from in excess of 330 km/h (205 mph) to 120 km/h (74 mph) over a distance of just 122m, pulling an enormous 5.6G in the process.

1 / 4

But it’s not just the intensity of braking that puts the brake systems under such strain in Montreal - it’s the frequency. With so many big stops coming so close together, the brake discs and pads have barely a moment to cool, and that can have major issues in terms of brake wear, especially if the ambient temperature is also high or if a driver is running in the hot air behind another car.

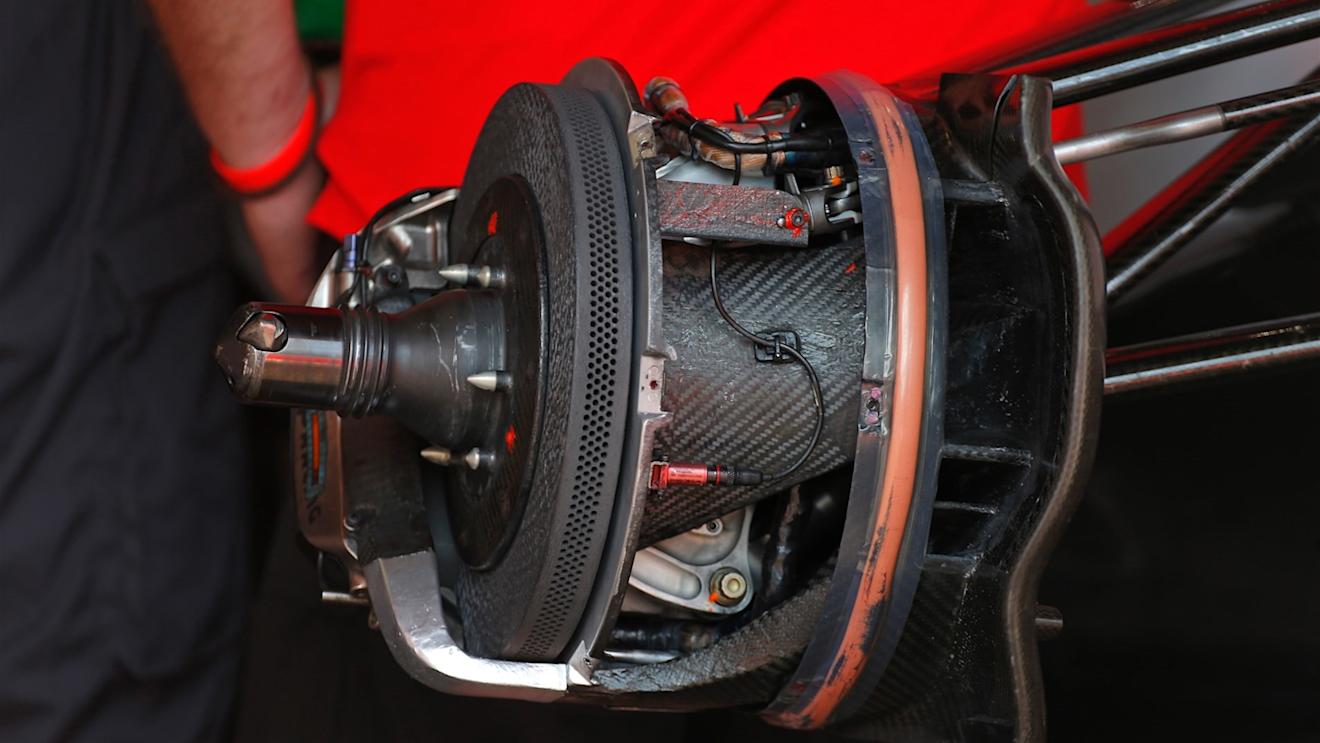

The carbon brakes used in F1 racing come into decent working temperature at around 450 degrees Celsius, but peak brake temperature in Canada will regularly exceed 1,000 degrees Celsius. However, this figure must be considerably lower by the time the driver gets to the next corner or he’ll find that his brake discs will start to wear dramatically, losing crucial performance in the process.

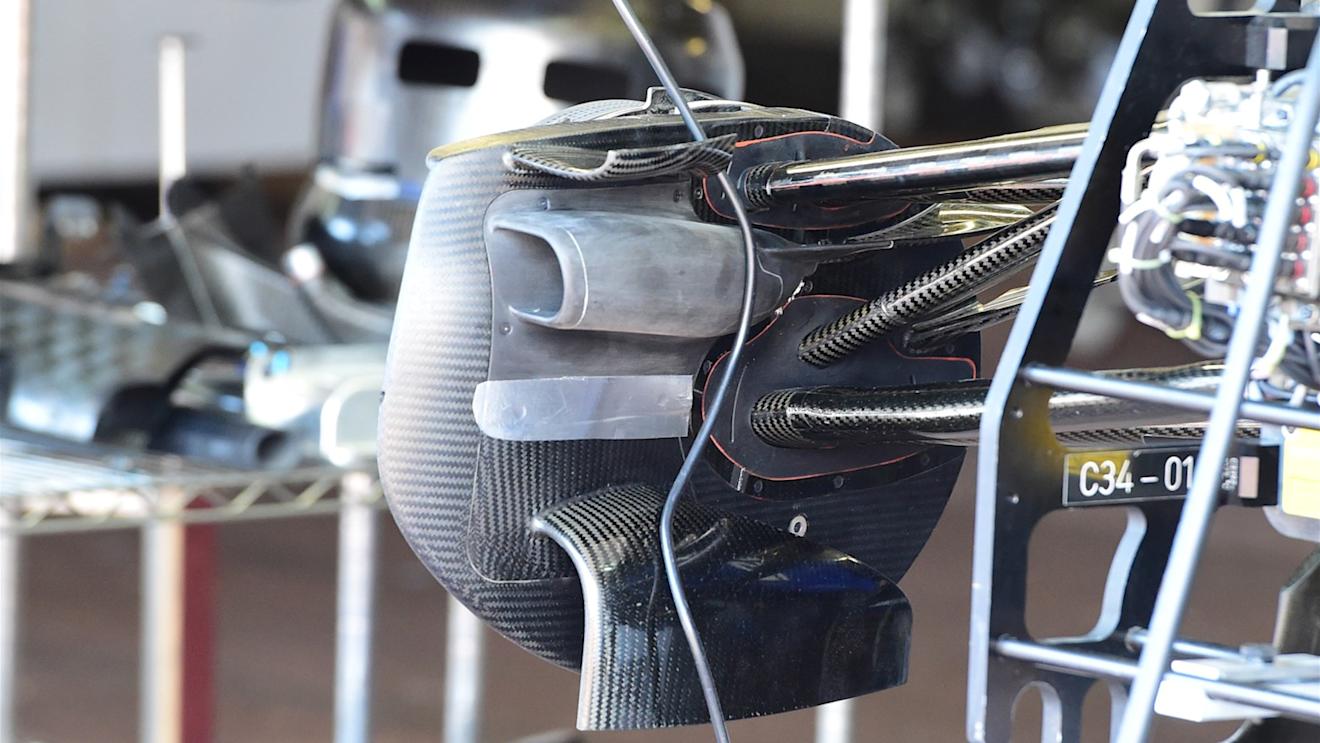

That puts enormous pressure on the teams to get optimise their brake cooling systems, and complex CFD simulations will be run ahead of the event to make sure they are up to task. Unsurprisingly the teams also all use the maximum permissible thickness of discs and pads in Canada.

Of course, since 2014 when the current breed of ERS-assisted power units were introduced, teams have been allowed to implement electronically-controlled rear brake systems so that the drivers are able to maintain a reasonable level of balance and stability under braking. This in turn enabled them to save weight by running smaller rear brakes and callipers. However, as Mercedes’ Lewis Hamilton found to his cost last year, if the MGU-K develops a problem and stops providing the same drag on the rear axle, this leaves the rear brakes incredibly vulnerable to excessive wear.

You might be able to get away with such a problem at a low brake energy circuit like Silverstone, but not in Canada where Brembo say each car produces around 147kWh of energy - more than enough to power a fridge for a year.

It’s little wonder then that the Italian manufacturer describes the race in Montreal as “without a shadow of a doubt the most demanding test bench for single-seater braking systems.”